Navigating through modern technological developments, the manufacturing sector is rapidly growing through leveraging AI-powered technologies. Aiming at fine-tuning production processes, modern-day enterprises are strategically focusing on building blocks of AI-enabled modern manufacturing. Some of its aspects include autonomous robotic technologies and streamlined operations.

Moreover, this is a newly adopted concept among leading organizations. Transforming raw materials into finished goods utilizing workforce skills, technology, heavy equipment, and complex processes, artificial intelligence in industrial automation aims at creating a secure and scalable business framework that can support the company’s objectives.

According to a study by McKinsey, Manufacturers using AI for maintenance reduce downtime by up to 50%, saving millions in operational costs.

Focused on parameters like optimized inventory levels, it allows incorporating data-driven intelligence in the planning process and improving productivity and operational excellence. Hence, paving the way for enterprises to save millions of dollars on conventional manufacturing processes, this futuristic technology is the way to go.

Our article presents an immersive study exploring the dynamics of manufacturing AI. Expanding the decision makers’ knowledge, it also discusses the use cases of AI related to manufacturing and some industry examples. Overall, this will enable you to deliver high-quality workflows and assist in cost reduction.

Industry Overview of AI for the Industrial Automation Sector

Understanding the power of artificial intelligence from a corporate lens enables business leaders to analyze its impact on a macro level. Looking forward to modernizing production practices through AI and ML in manufacturing, decision-makers must closely examine industry statistics of this growing sector.

As per research conducted by Markets and Markets, the valuation of this sector is projected to reach approximately USD 155.04 billion by 2030, with a CAGR of 35.3% from 2025 to 2030. Witnessing rapid expansion, a new concept known as smart manufacturing is taking over the industry, offering valuable attributes like interconnected systems, data intelligence, sustainability-oriented workflows, and the integration of modern tech. It integrates emerging technologies such as Industrial Internet of Things (IIoT), AI, Additive Manufacturing, Digital Twins, and AR/VR, Cybersecurity in Manufacturing.

Additionally, technological integrations like big data analytics, ML algorithms, and industrial robots bring in the development of more nuanced and detailed strategic measures in industrial engineering. Thus, targeted to deliver higher ROI, AI is working towards delivering world-class products at optimized costs, delivering the following outcomes:

- Predictive modelling has helped reduce downtime and operational cost by 30-50% and 40% simultaneously, as reported by research conducted by Deloitte.

- Additionally, the defect metric is reduced by 35% along with other cost reductions.

- Furthermore, studies also depict an improvement in the service levels of the manufacturing giants.

These insights substantiate that AI in industrial engineering is a valuable investment. Hence, enterprises are building on their computing capabilities to achieve these proven business-oriented results.

Understanding the Role of Artificial Intelligence in Manufacturing to Build Smarter and Better Strategies

AI in manufacturing plays a pivotal role in the strategic optimization of product development and resource utilization. Introducing the power of precision and agility in operations, business leaders are unlocking the potential for smart manufacturing to achieve unparalleled efficiency.

It contributes to the following fundamental processes, as mentioned below:

- It enables the strategic automation of repetitive everyday tasks, allowing personnel to spend more time on more critical and business priority processes.

- With AI-integrated equipment, data-driven metrics are part of manufacturing processes, helping in smoother, speedier, and more accurate real-time decisions.

- Predictive analytics also opens up a whole gamut of possibilities for the manufacturing industry, like optimizing production schedules in the factory and minimizing equipment downtime.

Hence, this sphere of technology-enabled smart factory solutions is reshaping the business processes to deliver higher-quality output.

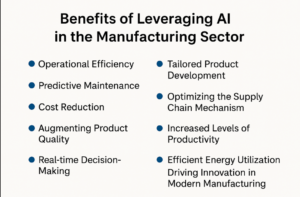

Benefits of Leveraging AI in the Manufacturing Sector

Modern AI-integrated manufacturing practices unlock transformative benefits for businesses. Ranging from streamlining operations and boosting productivity to minimizing downtime and ensuring top-tier product quality, AI empowers smarter decision-making while driving efficiency and innovation. Deploying AI manufacturing solutions can further boost the productivity of operations and workflows.

Moving forward, let’s understand the benefits of AI in manufacturing from a business point of view.

-

Enhancing Operational Efficiency

By leveraging NLP and ML algorithms in AI chatbot development, enterprises can deliver more engaging user experiences. This further helps in task automation, answering customer queries, streamlining workflows, reducing operational downtime, and improving overall efficiency.

-

Predictive Maintenance

AI-powered systems working on optimized algorithms can effectively predict equipment failures before they occur. It reduces unplanned downtime by up to 50% and also extends the machinery lifespan.

-

Augmenting Product Quality

Artificial intelligence in quality control systems (QC) can detect defects with high accuracy. Enhancing precision, QC systems help enterprises ensure the delivery of a superior product standard while optimizing operational costs.

-

Focus on Cost Reduction and Sustainability

Cost can be minimized by improving the intricate inventory and supply chain networks. AI in the supply chain also helps drive sustainability by reducing energy consumption.

-

Real-time Decision-Making

AI technologies process huge volumes of data to provide real-time insights to businesses. This significantly enables speedier and more effective decision-making based on data-driven intelligence, which aids in demand forecasting.

-

Tailored Product Development

By analyzing vast amounts of data to identify customer preferences, artificial intelligence enables manufacturing businesses to develop tailored products and meet the potential industry demand.

-

Optimizing the Supply Chain Mechanism

Intelligent AI technologies can forecast demand fluctuations in supply chain management. This aspect helps balance inventory levels while enhancing vendor relationships. It further enhances the operational agility, enabling rapid delivery of working products.

-

Increased Levels of Automation

Future-ready technologies like Robotics have also contributed to enhancing automation-based efficiency in businesses. Moreover, the inclusion of Cobots (Collaborative Robots) has also increased productivity while reducing human error. These assist modern enterprises in scaling their production without compromising quality standards.

-

Efficient Energy Utilization

Aiming towards sustainability, manufacturers optimize energy consumption through real-time monitoring and predictive maintenance. This aids in waste reduction and significantly lowers operational costs.

-

Driving Innovation in Modern Manufacturing Processes

Serving as a catalyst for creative work, AI tools help in analyzing data trends based on which enterprises can bring in new product ideations and prototypes, testing them for viability. Additionally, AI chatbots and virtual assistants help deliver more personalized customer experiences.

Emerging Technologies of AI in Manufacturing

Latest Technologies | Description |

Generative AI for Manufacturing |

|

AR/VR |

|

Blockchain |

|

Big-Data Analytics in Manufacturing |

|

Robotics in Manufacturing |

|

Types of Software for the Manufacturing Industry

In today’s fast-paced world, staying ahead requires more than just machinery—it demands the right manufacturing software solutions to optimize efficiency, reduce costs, and improve overall productivity. Software developments play a critical role in ensuring seamless operations, from designing products to managing inventory, monitoring equipment, and automating production lines.

Without further ado, let’s take a closer look at the crucial software adopted by manufacturing companies. This segment also covers how they work and why they are essential for modern manufacturing success.

Latest Software | Description | Examples |

Enterprise Resource Planning (ERP) | It integrates core business processes like inventory, production, and finance into a single platform for seamless operations. | SAP ERP, Oracle NetSuite, Microsoft Dynamics 365. |

Product Lifecycle Management (PLM) | It is designed to manage the product lifecycle, enhancing collaboration and innovation from concept to disposal. | Siemens Teamcenter, PTC Windchill, Dassault Systèmes ENOVIA. |

Industrial Automation and SCADA Systems | Supervisory Control and Data Acquisition (SCADA) systems use AI in industrial automation to monitor industrial processes in real-time, ensuring improved efficiency and reduced downtime. | Ignition, Wonderware, WinCC. |

Supply Chain Management (SCM) | These systems optimize procurement, logistics, and inventory, ensuring a streamlined supply chain process. | SAP SCM, Oracle SCM, JDA Software. |

Quality Management System (QMS) | QMS is a leading software solution used by the leading AI manufacturing companies. It ensures compliance by monitoring and controlling production quality across processes. | MasterControl, ETQ Reliance, IQMS. |

Predictive Maintenance Software | It forecasts equipment failures and schedules maintenance, reducing equipment downtime. | IBM Maximo, GE Predix, Augury. |

Industrial Internet of Things (IIoT) Platforms | IIoT platforms connect machinery and devices for real-time data collection, predictive analytics, and process optimization. | PTC ThingWorx, Siemens MindSphere, AWS IoT. |

Robotics and Automation Software | It helps automate repetitive tasks in manufacturing processes, thereby improving industrial efficiency. | ABB RobotStudio, FANUC ROBOGUIDE, KUKA Sim |

Additive Manufacturing Software | Facilitating 3D printing, this industrial software supports the design and production process of complex and custom parts. | Ultimaker Cura, Autodesk Netfabb, Stratasys GrabCAD. |

Inventory Management Software | For better stock control, this software tracks the product development stages in real-time. | Fishbowl Inventory, Sortly, Zoho Inventory |

Leading Use Cases of Artificial Intelligence in the Manufacturing Industry

Cutting-edge AI infrastructure aids in optimizing the manufacturing processes, ranging from logistics to product development. Smart factory solutions, focused on continuous improvement and innovation, have also helped improve business efficiency across every stage of the production process.

Digging deeper, let’s look at some interesting use cases adopted by AI manufacturing companies.

-

AI in Supply Chain Management

It optimizes inventory management, along with focusing on demand forecasting. Moreover, AI in factory automation also helps predict and reduce downtime by predicting delivery routes.

One of the leading AI in manufacturing examples is as follows: Ford utilizes an AI-powered supply chain network to predict and respond to real-time disruptions. By embracing this change, the enterprise has considerably improved its warehouse efficiency while reducing downtime.

-

New Product Development with AI

AI and deep learning in manufacturing accelerate the product development cycle by leveraging data to identify consumer preferences, market trends, and design optimizations. Moreover, generative AI in manufacturing design has helped reduce product launch time, increasing its competitiveness.

Discussing another artificial intelligence in manufacturing case study: Nike has optimized its product design, thereby launching innovative programs like Nike By You. This has helped them analyze dynamic consumer trends, streamlining the development process and delivering a high-quality product.

-

AI-Driven Warehouse Management

Automation has improved warehouse management systems like inventory tracking, sorting, and order fulfillment. So, with AI-enabled technologies, factories can efficiently manage stock levels, ensuring that the right products reach customers faster.

AI in manufacturing case study: Amazon leverages the power of AI in robotics and smart inventory systems in its fulfillment centers, enabling quicker order fulfillment while supporting workforce safety measures.

-

Accurate Demand Forecasting

AI’s predictive capabilities have helped manufacturers forecast demand with greater accuracy using machine learning in the manufacturing industry. As a result, businesses can align their production schedules to meet market demand while balancing their inventory levels.

Example: Unilever utilizes AI and ML to forecast demand across its product range, ensuring better alignment and management of its production schedules.

-

Quality Assurance with AI

AI for manufacturing quality control streamlines processes by automating defect detection and ensuring the delivery of superior product quality. Using machine learning applications in manufacturing, such as image recognition and deep learning, AI systems identify quality issues in real time, reducing the risk of defects, improving product quality, and lowering re-work costs.

Another machine learning use case in manufacturing is as follows: BMW implements AI-powered quality control systems to detect defects during production, reducing production defects by up to 40%, ensuring consistent product quality, and reducing re-work costs.

-

Collaborative Robots in Manufacturing

Cobots work alongside human operators, assisting with repetitive or hazardous tasks. Aiding in boosting manufacturing efficiency by increasing production speed significantly, they also help enhance workforce safety by performing risky tasks.

Example: FANUC has integrated cobots into its assembly lines, increasing production efficiency while also improving worker safety by allowing robots to handle dangerous tasks.

-

Optimize Manufacturing Performance

AI in the operations management sector enhances manufacturing performance by optimizing workflows and labor productivity. With the help of AI algorithms, manufacturers can monitor and improve key business metrics like overall equipment effectiveness (OEE), enabling continuous improvement, better uptime, and more efficient production runs.

Example: Tesla uses AI-driven automation to optimize its production lines, reducing bottlenecks and enhancing production speed, significantly boosting overall factory efficiency.

-

Streamlined Administrative Tasks Offering Sustainable Manufacturing Solutions

Another use of AI in the manufacturing industry is to simplify administrative tasks by automating document management, scheduling, and data entry processes. Furthermore, this ultimately improves organizational efficiency and reduces operational costs, while focusing on reducing emissions and carbon footprint.

Example: Forecasting a bright future of AI in manufacturing owing to its power-packed capabilities, Siemens has invested in automating its administrative processes through AI-powered intelligence, enabling faster processing times, reducing manual workload, and allowing staff to focus on more strategic business initiatives.

-

Smart Order Management

Intelligent order management is designed to automate and track inventory updates in supply chain management. This enables real-time monitoring, accurate and timely order fulfillment, and reduced delays. Enabling manufacturers to maintain optimal stock levels, they comprehensively contribute to providing a seamless customer experience.

Example: Zara leverages AI and ML in manufacturing to automate its inventory and order management system. This enhances the business system’s ability to monitor stock levels, predict demand, and streamline order fulfillment to ensure timely deliveries.

-

Connected Factories for Communication

AI-powered connected factories integrate the computing capabilities of AI, IoT, and Big Data. This interconnected ecosystem enables smarter decision-making, faster problem-solving, and improved efficiency.

Example: A major player utilizing AI for Industrial Automation, Siemens has implemented connected factory technology across its plants, enabling seamless data flow between equipment and production systems. This has enabled improving its decision-making and reducing its lead times by 15%.

Complex Hurdles for Implementing AI in Manufacturing and Their Modern Solutions

Implementing AI in manufacturing can drive innovation and operational efficiency, but it comes with its own set of challenges. Let’s dive into understanding these obstacles and their technology-enabled solutions for manufacturing.

1. Integration with Legacy Systems

Challenge

Legacy systems have redundant software programs and algorithms that are not compatible with the modern technologies of artificial intelligence. This creates a hurdle in system integration, which is a complex and costly process. Furthermore, it also affects the overall data quality management.

Solution

Its resolution lies in adopting a phased approach to integration. For smoother integration, enterprises must opt for legacy application modernization for manufacturing.

It is recommended to hire a seasoned AI development agency as they specialize in implementing AI tools in isolated high-priority segments like predictive maintenance, while gradually expanding the adoption of AI as business systems become more technology-ready. Moreover, they also assist in improving data management systems through leveraging IoT-integrated technologies.

2. Lack of Skilled Workforce

Challenge

Leveraging AI and machine learning algorithms requires specialized skill training to get the best output. Manufacturing businesses need to assess this skill gap among their workforce to properly implement and manage AI technologies.

Solution

Hence, enterprises should focus on upskilling their personnel strategically without disrupting the flow of operations, as AI and data analytics training programs are the bread and butter for future business optimizations. Generative AI training also cannot be overlooked.

3. High Initial Investment Costs

Challenge

The upfront investment required for adopting AI in industrial automation can be a significant barrier for many manufacturers, especially small to mid-sized companies.

Solution

To overcome this, manufacturers can explore AI-as-a-Service (AIaaS) models offered by cloud providers. These solutions reduce the need for heavy capital investment, offering scalability and lower upfront costs.

4. Change Management and Resistance

Challenge

This challenge implies resistance towards manufacturing automation and intelligence in processes among the employees and management. Personnel are usually wary of AI technologies due to the instilled fear of layoffs and job displacement in established workflows.

Solution

Hence, successful AI implementation requires clear communication of its benefits and job growth opportunities among the employees. Making them part of the process will help ease this hurdle, offering incentives for AI adoption. A culture supported by dependable manufacturing IT support strengthens trust and accelerates sustainable transformation.

Steps to Implement AI in Manufacturing Operations

Implementing AI in the manufacturing industry is a strategic process that can greatly enhance productivity, reduce costs, and improve product quality. Here’s a concise, step-by-step process for an impactful AI adoption in manufacturing:

1. Define Objectives

Start by identifying the aligned organizational goals that can revamp your manufacturing process—such as predictive maintenance, quality control, or supply chain optimization. You must also focus on redefining KPIs to track real-time metrics.

2. Feasibility Study and Choose the Right AI Solution

This step assesses the enterprise infrastructure and data’s readiness to adopt artificial intelligence. Here, companies must evaluate whether AI technologies like machine learning or computer vision can integrate seamlessly with the existing softwares. Additionally, enterprises must decide whether to develop an in-house AI system or partner with an AI development services provider.

3. Integrate AI into Existing Systems

The next step is ensuring that the AI integrates smoothly with existing infrastructure, such as Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), or Supply Chain Management (SCM) systems. To ensure seamless integration, enterprises are strongly advised to consult with an AI integration services provider, enabling accurate and efficient data flow between AI tools and other business systems.

4. Data Collection and Preprocessing followed by Training AI Models

Now, enterprises must work on preprocessing the fragmented data to achieve clean and validated datasets for AI-powered manufacturing solutions. Once the data is prepared, your AI development provider can train the AI models to recognize patterns or make predictions.

5. Pilot Implementation

Moving forward, you must consider conducting a pilot program by deploying the AI transformation solutions in a limited area. This helps identify any issues and allows for fine-tuning before a full-scale rollout. Monitor the results closely and adjust the system as needed.

6. Employee Training and Optimization

To ensure the smooth adoption of AI in manufacturing, enterprises must also invest in training employees on how to interact with AI-enabled manufacturing solutions. Helping them understand the benefits and how AI will complement their work, improving productivity and reducing errors, will bring an environment of acceptance for this new technology adoption.

7. Following the Feedback Loop

Continuously monitor the AI system’s performance using the set KPIs. Based on these results, you can refine and retrain AI models to implement the feedback from the production floor to maintain system efficiency.

By following these steps, businesses can successfully integrate AI and machine learning in the manufacturing industry, leading to smarter operations, cost reductions, and improved product quality.

Inspiring Industry Examples of AI in Industrial Automation

A globally leading company, Nike, has a tech-savvy customer base with evolving consumer preferences. They were faced with the issue of high return rates on their online platforms, which impacted their operations significantly. It even raised a question about their metrics related to the loyal customer base they have earned in the market.

Understanding the needs of these tech-savvy customers is the first and foremost step that they worked on. These are highlights below:

- Need for hyper-personalization

- Creating an interactive experience for Gen Z’s shopping online

- Significant shift towards online shopping

Based on AI and ML applications in manufacturing, the reputed enterprise worked on the following solutions to achieve its expected goals.

-

Personalization in Product Recommendations

An excellent use case of ML in manufacturing, Nike focused on analyzing extensive customer data, including their browsing and purchasing trends. Utilizing these trend analyses to provide tailored solutions to the users on app and online platforms, the company was able to provide the customers with a seamless interactive experience.

-

NLP Assistants

This aspect focused on utilizing the virtual assistants’ technology across their digital platforms. Enhancing the user experience, these technologies assist in delivering top-notch real-time customer support, along with catering to personalized product searches and order tracking.

Opting for such innovative AI manufacturing solutions, Nike gained a high level of customer trust, delivering exceptional product quality while minimizing defects in their automotive software solutions. Thus, the innovative artificial technologies are not only enhancing every aspect of the manufacturing process but also reshaping its dimensions altogether.

How SparxIT’s Tailored AI Development Solutions For Manufacturing Enhance Productivity

Transform your manufacturing operations with SparxIT’s tailored supply chain software development services, designed to streamline processes, enhance productivity, and drive innovation. Our AI-powered solutions help enterprises harness the power of data, optimize supply chains, and predict maintenance needs before they cause disruptions. Integrating AI into your manufacturing software systems will also enable smarter decision-making while optimizing cost and product quality.

SparxIT’s tailored AI solutions are designed to meet your specific needs, whether it’s predictive maintenance, real-time analytics, or quality assurance. Our AI and machine learning expertise empowers manufacturers to stay ahead in a competitive market, driving operational efficiency and enhancing overall performance. With SparxIT, experience seamless AI transformation services that boost productivity and ensure sustainable growth in the rapidly evolving manufacturing industry.

Want to Integrate AI in Manufacturing?

Frequently Asked Questions

How does artificial intelligence benefit the manufacturing industry?

AI enhances efficiency, reduces costs, predicts maintenance needs, improves product quality, and optimizes supply chains, leading to smarter decision-making and higher productivity.

How can AI increase production speed in manufacturing?

AI increases production speed by automating repetitive tasks, optimizing workflows, reducing downtime with predictive maintenance, and enabling real-time data-driven decision-making for faster operations.

What are the challenges of implementing AI in manufacturing?

Challenges of integration include data quality issues, integration with legacy systems, high costs, workforce skill gaps, and resistance to change from employees and management.

What are the core technologies behind AI in manufacturing?

Core technologies include machine learning, deep learning, computer vision, natural language processing, Internet of Things (IoT), and robotics, all integrated to optimize manufacturing processes.

What are the key use cases of AI in manufacturing?

Key use cases include predictive maintenance, quality assurance, supply chain optimization, demand forecasting, robotics, and process automation to improve efficiency and reduce downtime.