Digital transformation is changing the entire ecosystem of the manufacturing industry at an alarming rate. If CIOs don’t act now, they risk falling behind. Sticking with outdated systems, labor shortages, and legacy tools will only drag the manufacturing business down.

Why are we saying this? This is because these hurdles slow growth and eat into profits. Therefore, to remain a dominant force in the market, manufacturing companies must invest in the right digital tools.

Digital transformation in manufacturing isn’t about leveraging intelligent software and a future-ready AI tech stack. It’s a complete shift in how businesses think, work, and grow to uncover new efficiencies, drive better decisions, and offer customer-focused outcomes. It’s not just about keeping up, but rather about leading the change.

In this blog, we’ll explore how digital transformation turns pain points into competitive advantages for modern manufacturers.

What is Digital Transformation in Manufacturing?

Manufacturing digital transformation means using new digital tools to make the entire manufacturing process smarter and faster. It can be done through overall system modification or implemented in a phased manner. The goal of digitalization in manufacturing is to improve how things operate, how customers are served, and how data is used.

This change often starts with custom software development and smart systems. For example, factories use robotic process automation (RPA) to handle routine tasks, mobile apps to manage teams, and 3D printers to speed up production. Even back-end systems like ERPs help facilitate planning and reduce errors. It’s all about working in tandem with a clear digital transformation strategy.

To stay competitive, manufacturers can’t afford to ignore digital transformation. It’s no longer a nice-to-have. It’s a must. In fact, IDC expects global spending on digital transformation to hit over $3.4 trillion by 2027, with manufacturing leading the way.

Another report shows that over 90% of leaders see digital transformation in the manufacturing industry as key to their success. That says a lot. Therefore, building a solid digital transformation roadmap for manufacturing is critical for ROI and business agility.

However, there are a few aspects you need to keep in mind before adopting IT solutions for manufacturing industry, such as:

- Manufacturers often face many challenges at once, which makes implementing digital transformation solutions scattered and overwhelming.

- An unplanned approach often results in wasted resources and missed goals.

- According to Harvard Business Review, most companies are investing in digital transformation in manufacturing, but only a small share of the expected gains are being realized.

- The most successful IT manufacturing industry transformations are tied directly to clear business goals and measurable outcomes.

When done right, manufacturing digital transformation can increase efficiency, cut costs, and help companies move faster, serve customers better, and attract more investors.

Digital manufacturing transformation is being recognized as a vital shift toward more intelligent, efficient, and connected operations. The manufacturing sector is moving from traditional systems to data-driven processes where technologies such as IoT, AI, and analytics are playing a central role. A clear, step-by-step approach is required to ensure that every initiative delivers measurable value.

Step 1: Current Digital Readiness Should Be Assessed

An evaluation of the existing digital environment must be conducted. Tech leaders are encouraged to identify technology gaps, process inefficiencies, and areas suitable for automation. This assessment provides a foundation for a structured plan toward effective digitization in manufacturing.

Step 2: Clear and Measurable Goals Must Be Defined

Transformation objectives should be clearly outlined and measurable. Targets such as reducing equipment downtime, enhancing quality control, or optimizing supply chain efficiency should be established. Clear direction helps ensure that digital efforts produce tangible outcomes.

Step 3: Legacy Infrastructure Needs to Be Modernized

A shift from outdated systems to cloud-based and connected platforms should be prioritized. Industrial IoT and edge computing technologies can be adopted to enable seamless communication between machines and systems. This modernization strengthens operational flexibility and data accessibility.

Step 4: Data Across Operations Should Be Integrated

Data from various systems, such as ERP, MES, and IoT sensors, should be unified. When data is consolidated, insights can be derived faster, and decision-making becomes more accurate. Integration also supports transparency across production and supply chain activities.

Step 5: Analytics and Artificial Intelligence Should Be Applied

AI and analytics can be implemented to predict maintenance needs, optimize production cycles, and improve product consistency. Predictive insights allow leaders to anticipate issues before they affect performance. Data-driven decisions strengthen operational excellence and resource efficiency.

Step 6: Cybersecurity Measures Must Be Strengthened

With the ongoing digitalization of manufacturing, data protection must be prioritized. Robust security frameworks, regular system audits, and employee awareness programs should be implemented to safeguard digital assets and maintain trust.

Step 7: Workforce Should Be Empowered with Digital Skills

Employees should be trained to use new tools and interpret data insights effectively. Continuous learning initiatives help teams adapt to evolving technologies. When employees are digitally skilled, transformation becomes smoother and more sustainable.

Step 8: Continuous Innovation Should Be Encouraged

Digital transformation should be viewed as a continuous process of improvement. Emerging technologies should be explored, and pilot projects should be tested and scaled. Ongoing innovation keeps organizations agile and competitive.

These 8 steps to digital transformation in manufacturing offer a practical path to achieve smarter operations, higher productivity, and long-term resilience. By aligning technology with strategic goals, manufacturing enterprises can build connected ecosystems that drive sustainable growth and operational excellence.

Benefits of Digital Transformation in Manufacturing

Digitalization in manufacturing industry is vast. It helps companies become safer, faster, more efficient, and more sustainable, all while keeping costs low. It’s necessary to meet growing customer demands and stay ahead of the curve. To truly thrive, manufacturers must embrace change from the inside out. That’s where digital transformation is crucial.

Let’s see some benefits of digital technology in manufacturing that one can expect:

1. Reduced Workplace Incidents

Safety comes first in any factory. With the right digital technology and manufacturing software, training becomes easier and more effective. Workers learn faster and safer.

For example, augmented reality can show step-by-step instructions in a visual way. It helps new workers understand complex tasks without confusion.

Real-time monitoring can also alert teams to unsafe conditions before accidents happen. It spots patterns and warns about faulty machines or risky situations.

2. Less Product Rework

Rework wastes time, money, and resources. But with digital transformation for manufacturers, factories can better manage product data and processes.

They can track production more closely and make sure workers always follow the most current instructions. This helps avoid mistakes, saves costs, and reduces waste.

3. Boost Customer Satisfaction

One significant impact of digital transformation in manufacturing industry is that it helps businesses serve their customers better. It creates smoother experiences, better products, and faster IT support for manufacturing. When your systems are smarter, everything from product design to quality of service improves. Customers notice that. And when they’re happy, they stick around.

Plus, these digital transformation strategies don’t just boost satisfaction. They also cut down on waste, fix errors faster, and make operations more efficient.

4. Build a More Sustainable Future

The biggest advantage of digital transformation is that it also supports sustainability. That means doing better business while being more considerate of the environment. For example:

- Designing with fewer or greener materials saves money and reduces both embodied carbon and the weight of the product.

- Analyzing bottlenecks in smart factories helps cut energy use and improve Overall Equipment Effectiveness (OEE).

- Remote support reduces technician truck emissions while also keeping machines running longer and lowering maintenance costs.

- Modular product design promotes repairability and circularity, and limits waste from constant redesigns.

Top Technologies Shaping Digital Transformation in Manufacturing Industry

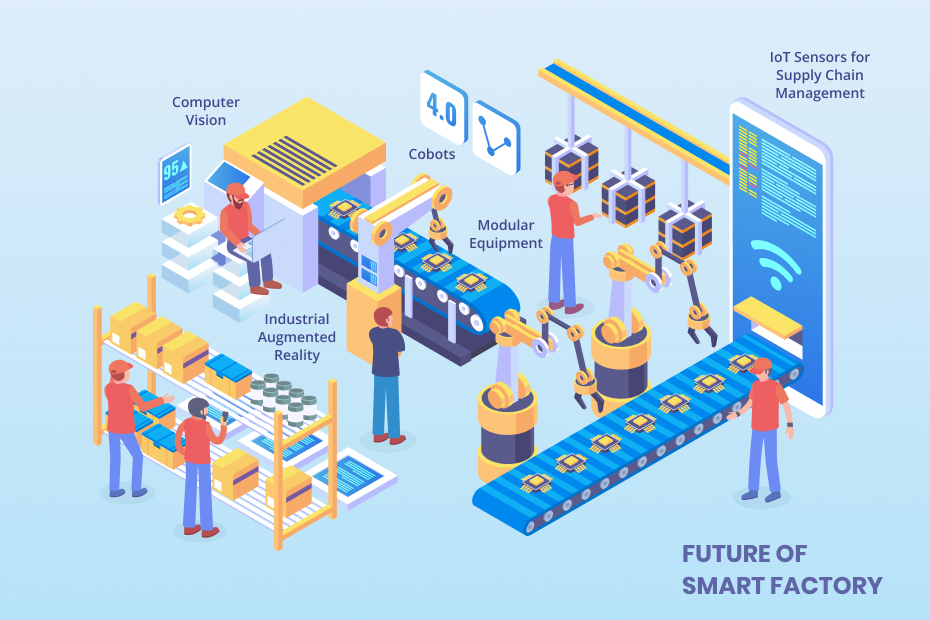

Let’s take a look at the top digital transformation trends in manufacturing industry. Technologies like AI, IoT, and big data are turning old-school factories into smart, connected, and data-powered operations.

1. Industrial IoT Sensors

These small devices are placed on machines and throughout the factory to track what’s happening in real-time. Whether it’s measuring temperature, checking gas levels, or tracking air pressure, IoT in manufacturing gathers real-time data to keep operations running smoothly.

Here’s how IoT sensors help digital transformation in industrial manufacturing:

- Monitoring plant operations and equipment

- Tracking and reducing energy consumption

- Managing inventory levels in real time

- Predicting and scheduling equipment maintenance

2. AI, Automation, and Machine Learning

Artificial intelligence (AI) is transforming the way manufacturers operate. With automation and machine learning, companies can do things faster, safer, and with fewer mistakes. These tools take over boring, repetitive tasks so that workers can focus on more important work.

However, to leverage automation in the manufacturing industry, you need to consult an experienced AI development services provider. They help companies spot trends early, improve product quality, and cut down on waste. That means faster production and better results.

Different companies use these tools in their own way. One might use AI to study customer orders and make sure they’re always delivering what people actually want. Another might use machine learning in manufacturing to look at shopping patterns and figure out what products customers are likely to buy next.

3. Augmented and Virtual Reality

Augmented and virtual reality may sound similar, but they’re actually quite different. With augmented reality (AR), digital information is added to the real world around you. It blends virtual content with what you’re already seeing, like directions on your phone screen while you look at the factory layout.

On the other hand, VR in manufacturing takes you somewhere entirely new. You wear a headset and get fully immersed in a digital world, completely separate from your real surroundings. You can see where you can place your products with proper dimensions and sizes.

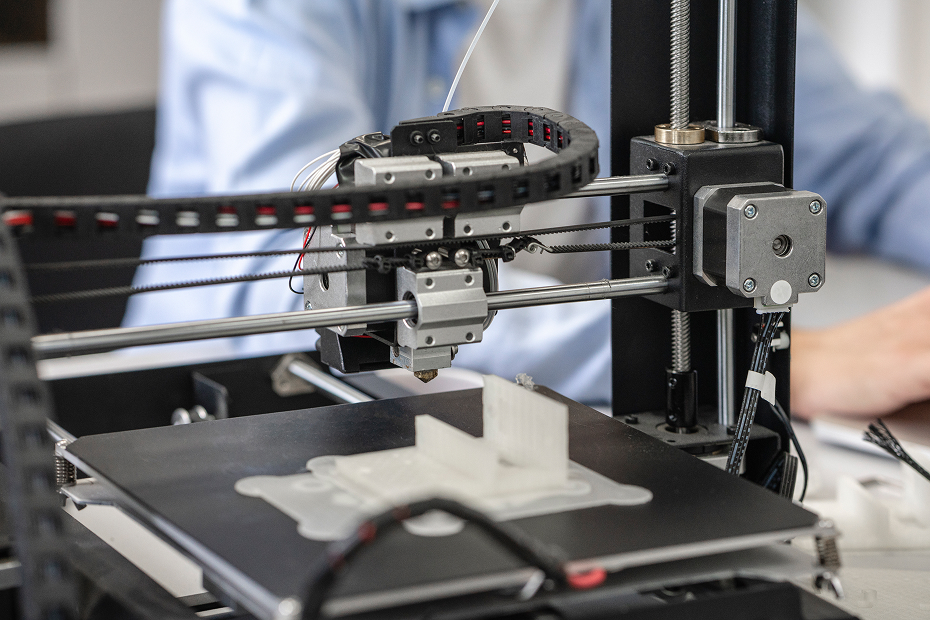

4. 3D Printing

Now let’s talk about 3D printing. It’s one of the most game-changing technologies in manufacturing today. This process turns digital designs into real objects by building them layer by layer using lasers and materials like plastic or metal. You can print full products or just the parts that go into them.

It’s already helping industries create faster, smarter, and more custom solutions. Many digital transformation companies are building 3D-based software that helps manufacturers connect with their printers.

5. Big Data Analytics

These may sound like tech buzzwords, but they play a significant role in how manufacturers operate today. Every day, companies create tons of data, from production numbers to customer orders. Big data analytics helps make sense of all that information. It shows what’s working, what’s not, and where improvements can be made.

By using this data wisely, manufacturers can predict trends early, plan better, and make smarter decisions about things like product design, inventory, and the entire digital transformation in supply chain. It’s like having a clear map in a very busy world.

Digital Transformation Examples in Manufacturing: Top 6

Every manufacturing company works differently. That means digital transformation isn’t a one-size-fits-all solution. What works for one company might not work for another. However, there are common digital transformation in manufacturing examples that can help leaders like CIOs and CTOs get started. Let’s look at them.

1. Transforming Processes

One major area of focus is process transformation. This involves product design, factory floor operations, or in-field services, and using technology in the manufacturing industry to improve those steps.

For instance, factories can use digital dashboards to monitor performance or redesign products to be easier to manufacture. The goal is to streamline operations, cut down delays, and save costs, all while working smarter.

2. Upgrading Products and Services

Another key area is transforming the products and services themselves. With customers expecting more choices and faster innovation, companies need to respond quickly. Digital tools make it easier to test new ideas, customize features, and improve quality.

Digital factory transformation also helps service teams predict and fix issues before they become problems. By feeding real-time data from product usage back into the design process, companies can keep improving.

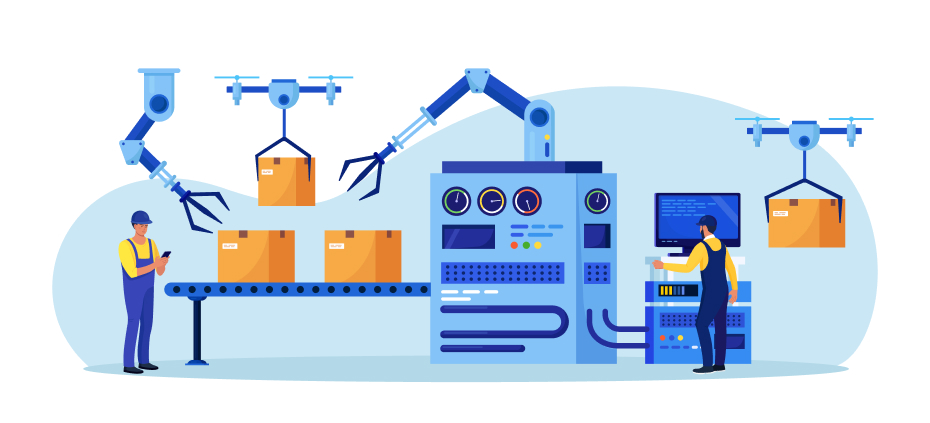

3. Smart manufacturing

Digital transformation in smart manufacturing is all about using modern tools and automation to make the entire production process quicker. Machines, systems, and software all communicate with each other constantly to collect and share data. It’s like giving your factory a brain that learns, adapts, and improves over time.

This smart approach can be used everywhere, from managing production lines to checking product quality or tracking supplies. The goal of manufacturing technology examples is to utilize modern technology to accomplish more, with fewer mistakes and less waste.

4. Marketplaces for CNC Machines and Parts

There’s been a rise in online marketplaces for CNC machines and parts. Manufacturing teams often need very specific tools to stay efficient. But finding replacements for legacy software modernization or rare parts used to be a hassle.

Now, specialized online stores make it easier. Machinists can browse, compare, and order CNC machinery, parts, and tools right from their screens. It saves time, avoids delays, and keeps production moving.

5. Predictive maintenance

Predictive maintenance in manufacturing is a smart way to keep manufacturing machines running smoothly. It monitors equipment and identifies early signs of wear or damage. Instead of waiting for something to break, it helps you fix issues before they turn into bigger problems.

It’s a bit like preventive maintenance, but smarter. Predictive systems, especially when connected with work order software, give you real-time insights. That means less downtime and more efficient operations.

Industries like automotive, oil and gas, agriculture, and even healthcare are already using it. These systems are always watching your machines, even when you’re not. They make small tweaks to keep everything running just right.

6. Quality control

Quality control also gets a big boost from AI in Manufacturing and machine learning. Cameras and IoT sensors scan products as they’re made, checking for defects instantly. If something looks off, the system flags it right away. This means fewer bad products, less waste, and less time spent fixing mistakes. It helps manufacturers keep their quality high without slowing things down.

Challenges of Digital Transformation in Manufacturing and Their Solutions

Digital transformation in manufacturing is moving fast, and every step forward brings new challenges. Manufacturers not only need to keep up with the pace but also make sure it drives real business growth.

Let’s look at manufacturing digital transformation challenges while integrating digital tools:

1. Misalignment with Digital Transformation Techniques

One of the biggest hurdles is getting everyone on the same page about the strategy. Even if a company has already started its digital journey, regular check-ins and updates are a must.

The strategy has to match business goals and show clear value. Without that alignment, it’s easy to lose direction and momentum.

Solution:

Consult with a digital consulting company to stay aligned with business goals through regular reviews, clear KPIs, and strong collaboration between leadership, IT, and operations teams.

2. Choosing Tech That Grows with Your Business

One of the toughest parts of digital transformation for manufacturers is choosing the right tech. The tools you invest in should help you innovate, but they also need to scale as your business grows.

If the technology can’t adapt, it’ll slow you down instead of speeding you up. So, it’s not just what you buy, but how well it fits with your long-term goals.

Solution:

Hire a manufacturing software development company with experience that can help you choose flexible, scalable tech that supports both your current needs and future growth.

3. Handling Change Smoothly

Change isn’t easy, especially in manufacturing, where processes are often people-driven and deeply rooted. Moving toward automation and digital techniques means rethinking how things are done.

It’s not just about the tools; it’s about how people use them. That’s where many companies struggle. But with the right approach, change becomes manageable. Working with a digital transformation services provider can help teams understand what’s needed and how to transition smoothly.

Solution:

Prepare teams early, communicate clearly, and bring in expert guidance to make the change less stressful and more successful.

4. Onboarding, Training, and Reskilling Employees

One of the major digital transformation in manufacturing challenges is getting your team up to speed with new tools. You can’t just bring in new software or machines and expect people to know what to do. Training takes time, effort, and planning. Some roles may need reskilling entirely. Whether it’s learning how to operate a robotic arm or navigating new software, the learning curve can be steep.

If your company already has training systems in place, great, you’re ahead. But many don’t, and that slows everything down. The real power of any technology comes when your people know how to use it well. Proper onboarding and training ensure your team gets the most out of digital transformation solutions in manufacturing and helps boost overall ROI.

Solution:

Build hands-on training programs, offer ongoing support, and cybersecurity services to help teams learn, adapt, and stay resilient with new tools.

5. Scaling Organization-wide to Avoid Silos

Another big challenge is making sure the digital transformation works across your entire organization, not just in small pockets. Many manufacturers struggle with team silos. Departments that don’t talk or collaborate well. When this happens, digital technology adoption gets stuck. One team might use a system fully, while another doesn’t even know it exists.

To make digital tools work company-wide, everyone needs to be on the same page. That starts with clear goals and open communication. When teams understand how their work connects and feel encouraged to share ideas, transformation picks up speed and sticks.

Solution:

Break down silos by setting shared goals, encouraging collaboration, and promoting an open culture across all departments.

Drive Digital Transformation in Manufacturing with SparxIT Expertise

As a leading digital transformation company, we serve globally, including the USA, UK, UAE, and beyond. We bring deep technical know-how and the latest tools to help modernize the manufacturing industry. Our services support you at every step, helping you move faster and adapt to market changes with ease.

Whether you need to modernize, improve, or fully transform your operations, our custom manufacturing software solutions make production smarter and more efficient. We dig into the root of problems, use data to find insights, and help boost product quality while cutting down inspection costs.

Partner with Experts

Frequently Asked Questions

Why is digital transformation important in the manufacturing industry?

It’s essential because it helps manufacturers stay competitive by making operations faster, smarter, and more efficient. It allows companies to meet evolving customer demands, reduce costs, boost productivity, and improve product quality, all while staying agile in a rapidly changing market.

What are the benefits of digital transformation in manufacturing?

Digital transformation brings a range of benefits like improved efficiency, better decision-making, fewer errors, and higher product quality. It also helps reduce operational costs, enhance safety, support innovation, and provide manufacturers with the flexibility to quickly respond to market changes and customer needs.

What are the biggest challenges in implementing digital transformation in manufacturing?

The main challenges include choosing the right technologies, getting teams aligned, reskilling workers, managing change, and avoiding data or team silos. Scaling solutions across the organization while keeping everything connected and valuable to business goals is often the toughest part of the journey.

What is the ROI of digital transformation in manufacturing?

The return on investment (ROI) can be significant. Companies can lower costs, improve productivity, reduce downtime, and enhance customer satisfaction. Over time, these gains lead to higher revenue, stronger market positioning, and more efficient resource utilization, making the investment well worth it when done correctly.

What are the key technologies and trends enabling digital transformation in manufacturing?

Key technologies include AI, IoT, machine learning, big data, and automation. Popular trends, such as predictive maintenance, smart factories, digital twins, and connected supply chains, are making manufacturing more intelligent, data-driven, and responsive to real-time demands and changes.