As the oil and gas industry faces rising costs, volatile demand, and sustainability pressures, big data analytics is emerging as a key enabler that empowers organizations to work smarter, safer, and more strategically.

Big data analytics for oil and gas enhances operational efficiency, improves decision-making, and reduces risks across the value chain. With exploration becoming more complex and production environments more unpredictable, data-driven intelligence enables energy companies to optimize drilling, forecast equipment failures, and manage assets with far greater accuracy.

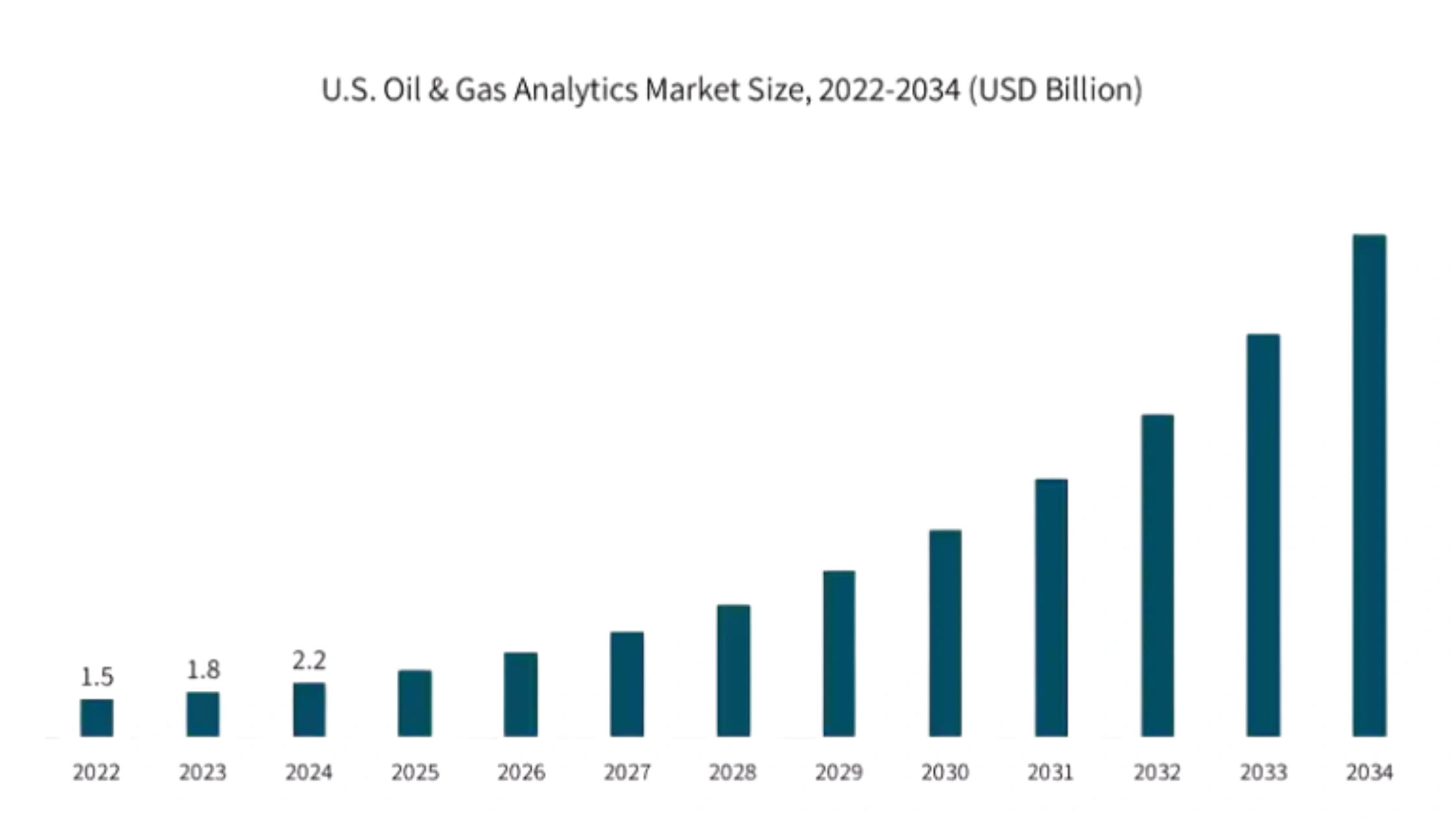

According to Global Market Insights, the oil and gas analytics market was valued at USD 8.9 billion in 2024 and is projected to grow at a CAGR of 25% through 2034. This is driven by the rapid adoption of digital oilfields, IoT-enabled monitoring systems, and AI-powered analytics.

In this blog, you’ll learn how big data analytics works in the oil and gas industry, its key components, real use cases, trends, and the value it brings to modern energy operations.

An Overview of Big Data in Oil and Gas

The growing complexity of exploration, production, and refining has pushed organizations to rely heavily on big data in oil and gas to interpret massive volumes of operational information. From seismic data interpretation and drilling optimization to IoT sensor outputs and SCADA systems, today’s energy companies generate data at a scale that traditional tools can’t manage efficiently.

To stay competitive, leaders across the big data in oil and gas sector use big data analytics services to gain visibility into subsurface conditions, track real-time equipment performance, and make more informed decisions.

How is big data in the oil and gas industry market segmented?

- By Component: Software, Hardware, Services

- By Data Type: Structured, Unstructured, Semi-Structured

- By Deployment: On-Premise, Cloud-Based

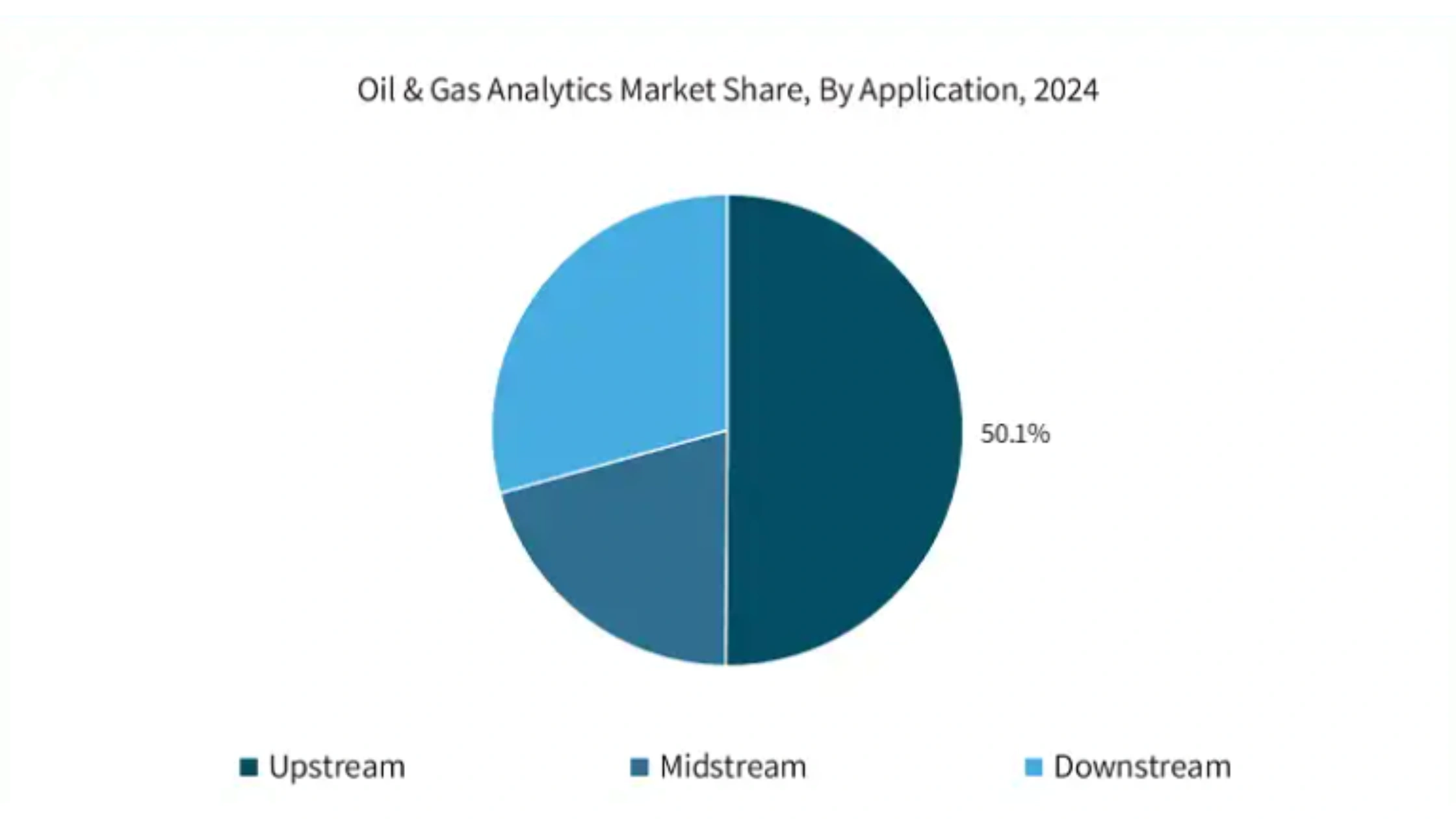

- By Application: Upstream, Midstream, Downstream, Administration

Real-time data analytics for oil and gas plays a central role in upstream (Exploration and Production) operations, where IoT sensors capture data from rigs, wells, and production sites. In fact, offshore big data analytics help teams resolve issues faster and significantly enhance drilling logs and production forecasting.

The upstream market size is projected to expand at a CAGR of over 23.8% through 2034. The upstream segment in oil and gas is segmented into three key areas:

- Raw materials: Crude oil, natural gas, and other sources

- Production sites: Onshore and Offshore

- Drilling technologies: Conventional and Unconventional methods

Types of Data Analytics in Oil and Gas Industry

The adoption of analytics in oil and gas industry relies on four primary types of analytics, which are mentioned below:

Descriptive analytics

It focuses on understanding what has already happened by analyzing historical production data, equipment failure prediction, and reservoir simulation using big data. This helps teams identify patterns and benchmark current performance against past operations.

Diagnostic analytics

This type of big data analytics in oil and gas digs deeper to explain why issues occur, helping teams identify the root causes of drilling delays or equipment failures. It provides clarity on operational hurdles and highlights areas that need immediate attention.

Predictive analytics

Predictive analytics in oil and gas industry uses statistical models and machine learning services to forecast potential risks, estimate well performance, and support safer, more informed planning. By anticipating future scenarios, companies can prevent disruptions and optimize resource allocation.

Prescriptive analytics

It is a core component of advanced analytics in oil and gas, which recommends the best course of action by combining AI-driven insights with operational constraints. It helps decision-makers choose strategies that maximize efficiency, safety, and cost savings.

Core Elements of Big Data Analytics in Oil and Gas Industry

Big data analytics relies on several core components that work together to make oil and gas operations smarter, faster, and more efficient. These elements strengthen data management in oil and gas industry processes and ensure that insights are accurate, timely, and actionable.

-

Data Collection and Integration

Modern operations depend on collecting data from sensors, connected machines, and field systems. By combining IoT and big data in oil and gas, teams can capture real-time information from wells, rigs, and pipelines, giving them a complete picture of what’s happening on the ground.

-

Data Storage Solutions

Cloud platforms, data lakes, and scalable storage systems help companies store massive amounts of structured and unstructured data. These cloud-based solutions make it easy to access historical and real-time information whenever needed, ensuring nothing gets lost or overlooked.

-

Data Processing Technologies

Processing tools like ETL/ELT pipelines and real-time engines clean, filter, and prepare raw data for analysis. This ensures that the data being used is accurate, consistent, and ready to generate meaningful insights.

-

Advanced Analytics Techniques

Machine learning, predictive modeling, and prescriptive analytics help teams understand patterns, forecast risks, and determine the best operational actions. These techniques turn raw data into powerful oil and gas business intelligence that boosts performance across the value chain.

-

Visualization Tools

Dashboards and analytics platforms transform complex datasets into easy-to-understand visuals. They help teams detect leaks using sensor data quickly and act on insights without digging through raw numbers or spreadsheets.

-

Data Security and Governance

Strong governance ensures that sensitive operational data is protected, well-managed, and compliant with industry standards. It plays a crucial role in digital transformation strategy, helping oil and gas companies maintain trust, data integrity, and secure access across teams.

Benefits of Big Data Analytics for Oil and Gas Companies

Big data is doing much more than automating tasks. It is changing the way oil and gas companies run their entire operations. Here are some advantages of big data analytics for oil and gas industry:

-

Improved Operational Efficiency

Big data gives companies a real-time view of what’s happening with their equipment and production lines. This continuous visibility helps teams quickly adjust operations to avoid disruptions and keep everything running smoothly.

-

Reduced Downtime

Instead of waiting for machines to break, pipeline monitoring analytics can warn teams in advance, allowing repairs to be planned early. This proactive approach not only prevents sudden breakdowns but also extends the lifespan of expensive equipment.

-

Enhanced Safety and Risk Management

Data analytics in the oil and gas industry constantly watches for unusual patterns that might signal danger, helping prevent accidents and keeping workers safe. Early detection also gives teams more time to respond, reducing the severity of potential incidents.

-

More Accurate Decision-Making

Whether it’s planning drilling activities or managing inventory, big data analytics in the oil and gas industry helps teams make decisions based on facts rather than gut feelings. With accurate insights, companies can choose strategies that deliver better long-term results.

-

Cost Optimization and Higher ROI

From cutting waste to improving equipment performance, big data helps companies run leaner and smarter, which ultimately boosts profits. Over time, these efficiencies add up, making operations more resilient and financially sustainable.

Top 10 Use Cases of Big Data Analytics in Oil and Gas Operations

Big data is transforming oil and gas by making exploration smarter, production faster, and operations safer. These real-world use cases show how analytics-driven intelligence helps companies save costs, reduce risks, and improve output across the value chain.

-

Exploration and Production Optimization

Big data analytics helps geologists interpret seismic surveys and identify the best drilling zones. These big data applications in exploration and drilling reduce uncertainty and improve well placement accuracy.

Example: Companies use seismic pattern analysis to avoid dry wells and maximize production potential.

-

Pipeline Monitoring and Transportation

Real-time analytics track pressure levels, flow rates, and pipeline vibrations to detect leaks or blockages early. Using sensors along pipelines, operators receive instant alerts when anomalies occur.

Example: Pipeline companies can shut down a section automatically when unusual pressure drops are detected.

-

Refining and Distribution

Refinery process optimization using data helps companies check temperature, pressure, and chemical ratios during processing. Data analytics services also help improve fuel blending and distribution efficiency.

Example: Real-time refinery data allows operators to adjust operations immediately to maximize output while saving energy.

-

Predictive Analytics in Oil and Gas

Predictive models analyze historical trends and real-time conditions to forecast drilling outcomes, production levels, or equipment risks.

Example: AI models can estimate well performance months in advance, helping companies plan investment and operational strategies more accurately.

-

Predictive Maintenance

Data analytics in petroleum industry enables early detection of machine wear and abnormalities by analyzing vibration, temperature, and pressure data.

Example: Predictive algorithms can warn engineers of compressor failures days in advance, preventing costly downtime and extending asset lifespan.

-

Safety Improvements

Worker safety improves when analytics detect unusual equipment behavior, hazardous gas levels, or structural weaknesses.

Example: Using oil & gas analytics, a drilling site may receive alerts about sudden pressure spikes that could lead to blowouts, allowing teams to act immediately.

-

Edge Computing for Real-Time Responses

Edge devices process data directly at the drilling site or offshore platform, enabling instant decisions without waiting for cloud servers.

Example: Edge analytics can automatically shut down a pump within milliseconds if it detects overheating or abnormal vibrations.

-

Digital Oilfield Modernization

Digital oilfields combine IoT, AI, and analytics to automate workflows and remote operations.

Example: Operators can manage entire offshore platforms from onshore control rooms, increasing efficiency and reducing the need for physical site visits.

-

Optimization of Supply Chain and Logistics

Big data analytics for oil and gas helps track inventory, predict demand, and optimize transportation routes.

Example: Analytics can calculate the optimal route for fuel delivery trucks by accounting for weather, traffic, and refinery output. It lowers fuel costs and reduces delays.

-

Supporting ESG and Energy Transition Goals

Big data helps companies accurately measure emissions, energy consumption, and environmental impact.

Example: Reservoir management using big data enables more effective water-injection planning, reducing waste and supporting sustainability targets.

Real-World Examples of Big Data Analytics in Oil and Gas Sector

With data analytics in oil and gas, operators can detect issues instantly, optimize field performance, and make smarter decisions with far greater accuracy. Many leading big data analytics companies are helping energy enterprises unlock value through AI, IoT, and advanced data models. Here are three real-world examples:

-

Aramco

Aramco leverages offshore big data analytics across its offshore platforms and refineries to identify equipment issues before they escalate. By analyzing vibration, pressure, and temperature data in real time, their teams can schedule maintenance in advance. This proactive system helps reduce downtime and increase equipment reliability.

-

Royal Dutch Shell

Shell uses big data analytics to monitor drilling equipment, pressure variations, and downhole behavior across deepwater rigs. Real-time insights help engineers prevent blowouts, reduce non-productive time, and optimize drilling parameters. By analyzing millions of sensor data points daily, Shell improves operational safety.

-

ONGC

In India, ONGC partnered with leading big data analytics companies to digitize its mature fields and enhance production forecasting. Using IoT sensors and AI-driven reservoir models, ONGC improves well planning, reduces water cut, and increases recovery rates. The use of big data has helped revitalize aging assets and boost India’s domestic energy output.

Challenges in Implementing Big Data Analytics for Oil and Gas

Adopting advanced analytics in oil and gas industry operations brings real value, but companies face several hurdles along the way. Below are the main challenges and practical solutions that help overcome them.

Challenge 1: Managing Massive Data

Oil and gas operations generate seismic data, sensor readings, drilling logs, and production reports at an enormous scale, making it difficult to process and interpret efficiently.

Solution:

Implement centralized data lakes and automated data pipelines that clean, organize, and unify information. This ensures teams can quickly access reliable data for analysis and decision-making.

Challenge 2: Legacy Systems

Many companies still rely on outdated software and hardware that cannot easily connect to cloud-based tools or modern analytics systems.

Solution:

Use API-based connectors and middleware to modernize legacy systems with new platforms. Gradual modernization helps companies adopt analytics without disrupting daily operations.

Challenge 3: Shortage of Skilled Talent

The rise of ML in the oil and gas industry’s workflow requires hiring data scientists, ML engineers, and domain experts, a talent pool in short supply.

Solution:

Invest in workforce upskilling and bring in an external big data analytics company. Collaborative teams help bridge the skill gap and accelerate digital transformation initiatives.

Challenge 4: Ensuring Data Accuracy

Data from offshore rigs, remote fields, or old sensors can be inconsistent or incomplete, affecting the quality of insights.

Solution:

Deploy sensor calibration routines, automated validation checks, and data governance frameworks to maintain high data quality across the value chain.

Challenge 5: Cybersecurity Risks

Connected systems, IoT devices, and cloud platforms expose critical infrastructure to potential cyberattacks.

Solution:

Adopt strong cybersecurity services, including encryption, access controls, and continuous monitoring, to protect operational data and maintain system integrity.

Emerging Trends in Oil & Gas Analytics

The latest trends in oil and gas show a major shift toward smarter, faster, and more automated decision-making. One of the biggest drivers of this shift is artificial intelligence data analytics, which is helping operators improve forecasting, automate workflows, and unlock deeper insights from massive datasets. Let’s look at the future trends of data analytics in oil and gas:

| Trend | Description | How It Helps |

| AI-Driven Analytics | Uses AI to automatically analyze seismic, drilling, and production data. | Enhances accuracy, decision-making, and reduces manual interpretation. |

| Digital Twins | Creates virtual models of wells, pipelines, and refinery units. | Predicts failures, tests operating conditions, and improves performance. |

| Edge Computing | Processes data at field locations instead of sending everything to the cloud. | Enables real-time alerts, faster shutdown decisions, and safer operations |

| Autonomous Operations | Incorporates AI-powered drilling systems and automated workflows. | Increases safety, reduces human error, and boosts operational efficiency. |

| ESG & Sustainability Analytics | Tracks emissions, water usage, and energy consumption. | Helps companies meet environmental targets, regulations, and sustainability goals. |

| Cloud-Based Analytics Platforms | Uses scalable cloud systems to store, process, and analyze big data. | Improves collaboration, reduces infrastructure costs, and speeds up data access. |

Accelerate Oil and Gas Operations with SparxIT’s Big Data Analytics Services

In an industry where every second and every decision matters, energy companies need partners who can turn complex field data into fast, actionable insights. As one of the leading oil and gas data analytics companies, SparxIT helps operators streamline their workflows, reduce uncertainty, and make confident decisions backed by real-time business intelligence.

We build custom oil and gas analytics software that brings together data from wells, pipelines, refineries, sensors, and enterprise systems into a single intelligent platform. With advanced analytics, AI-driven forecasting, and interactive dashboards, energy teams get the clarity they need to plan better, respond faster, and operate more safely.

From predictive maintenance and drilling optimization to supply chain efficiency and ESG reporting, we use big data analytics for oil and gas to transform raw data into strategic advantage. With our domain expertise and modern technology stack, decision-making becomes quicker, smarter, and more reliable.

Partner with Experts

Frequently Asked Questions

How is big data transforming the oil and gas industry?

Big data is transforming the oil and gas industry by enabling real-time decision-making, reducing operational risks, optimizing production, and improving asset performance.

How is big data used in oil and gas exploration and drilling?

Big data is used in oil and gas exploration and drilling to interpret seismic data, optimize well placement, reduce drilling risks, and improve reservoir understanding.

What are the benefits of predictive analytics in the oil and gas industry?

Predictive analytics in the oil and gas sector helps forecast equipment failures, reduce downtime, improve safety, and increase production efficiency.

How much does it cost to implement big data analytics in the oil & gas industry?

The cost to implement big data analytics in the oil and gas industry generally ranges from $30,000 to $300,000, depending on data volume, software requirements, infrastructure complexity, and the scale of analytics deployment.