Manufacturing isn’t just a backbone of the global economy, it’s a powerhouse. In 2023, manufacturing added $2.3 trillion to the U.S. GDP, accounting for 10.2% of the total economy, according to data from the Bureau of Economic Analysis (BEA). And now, with the emergence of Industry 5.0, this sector is undergoing a digital transformation, fueled by smart manufacturing and the rise of machine learning.

By 2032, the smart manufacturing market is expected to soar, from $260.56 billion in 2023 to an impressive $938.38 billion. That’s a compound annual growth rate of 15.3% during the forecast period (2025-2032). At the heart of this explosive growth is machine learning in manufacturing.

From optimizing complex processes to reducing downtime and improving product quality, MLOps solutions are set to revolutionize how factories operate. In this blog, we’ll dive into how machine learning is reshaping manufacturing, from its top benefits and real-world use cases to a practical implementation roadmap and the challenges you should watch out for. So, let’s get started.

What is Machine Learning in Manufacturing?

Machine learning (ML), a subset of artificial intelligence, uses algorithms to analyze data, uncover patterns, detect anomalies, and continuously refine its predictions. While ML powers everything from email filters to generative AI chatbots, it’s making a major impact on manufacturing.

Today, manufacturers are leveraging ML for predictive maintenance, quality control, supply chain optimization, and smarter production processes. By drawing insights from real-time data, sourced from IoT devices, ERP software, and external feeds, ML enables faster, smarter decisions on the factory floor.

For instance, it can track weather disruptions, reroute logistics, and even automate responses to minimize downtime. In short, ML is helping manufacturers boost efficiency, reduce waste, and stay resilient in a rapidly changing world.

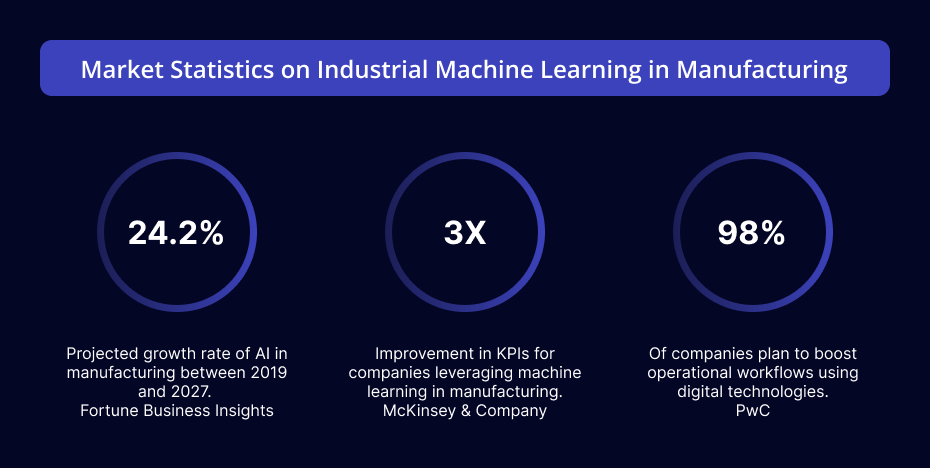

Market Statistics on Industrial Machine Learning in Manufacturing

Machine learning has become a powerful force behind the digital transformation in the manufacturing industry. By automating complex, labor and data-intensive processes, it’s helping business owners to make smarter, faster decisions.

Machine learning for manufacturing is streamlining every stage of the production cycle. It’s not just about cutting costs, they are creating more agile, future-ready, and intelligent manufacturing systems.

Still wondering how impactful it really is? Let’s dive into some eye-opening statistics that highlight just how much machine learning in manufacturing is reinventing the wheel.

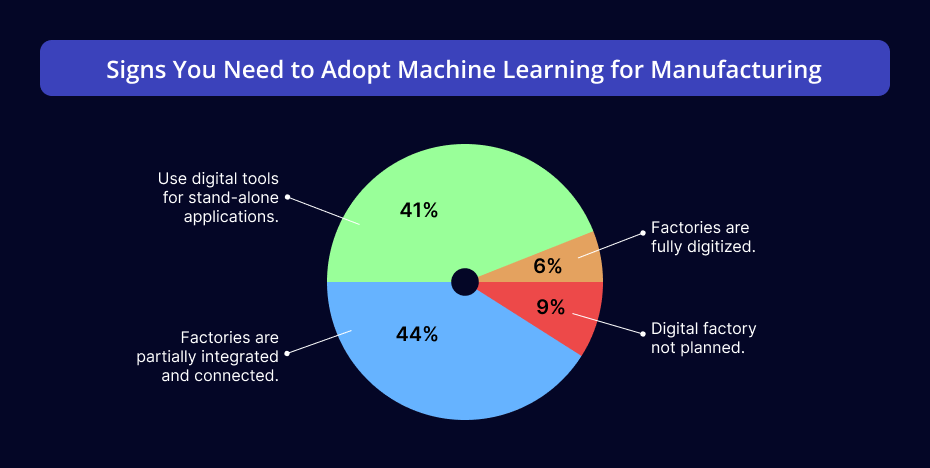

Signs You Need to Adopt Machine Learning for Manufacturing

Not sure if your manufacturing operation is ready for machine learning? If you’re facing any of the challenges below, it might be time to make the switch:

-

Unsafe Working Conditions

If your facility struggles with safety incidents, then time to look for ML in manufacturing. ML-powered robots and computer vision systems can prevent collisions, monitor risks, and ensure safer working environments in real time.

-

Frequent Machine Breakdowns

Predictive maintenance powered by ML helps manufacturers reduce downtime by forecasting equipment failures before they happen, minimizing disruptions, and extending the lifespan of critical assets.

-

Manual & Error-Prone Inspections

Machine learning significantly improves quality control with adaptive visual inspection tools that outperform traditional systems, offering precision even in variable production conditions.

-

Lack of Design Flexibility

ML-driven generative design accelerates product innovation by instantly generating optimized design alternatives based on defined constraints, empowering faster and more efficient development cycles.

-

Inaccurate Demand Forecasting

Advanced ML algorithms analyze historical data, market trends, and real-time variables to deliver highly accurate demand forecasts, improving supply chain planning and reducing excess inventory.

Benefits of Machine Learning for Manufacturing

At this stage of AI and machine learning adoption, most manufacturers already recognize its value across the entire organization. According to an MLC survey, the top reported benefits include better decision-making, improved planning, and stronger cost control. The survey also explored specific use cases and advantages of using machine learning in manufacturing, which we’ll cover below.

-

Increased Efficiency and Productivity

Machine learning automates routine tasks and optimizes production workflows, helping manufacturers boost efficiency by up to 20% while reducing errors and speeding up overall output.

-

Customization and Personalization

With ML, manufacturers can analyze customer preferences and adjust production lines to deliver personalized products, driving up customer satisfaction and increasing conversion rates by nearly 30%.

-

Safety and Compliance

ML-powered systems help monitor safety hazards in real time, ensuring better compliance with regulations and reducing workplace incidents by up to 40% through predictive analytics.

-

Energy Efficiency

By analyzing energy usage patterns, ML can optimize machine operations and cut unnecessary consumption, leading to energy savings of 15–25% across manufacturing facilities.

-

Data-driven Insights

Machine learning turns massive amounts of factory data into actionable insights, enabling smarter decisions, forecasting, and continuous process improvement with up to 90% accuracy.

-

Cost Savings

From predictive maintenance to reduced waste, ML-driven automation can lower operational costs by 10–30%, making manufacturing more profitable and scalable over time.

ML-Based Technologies Driving Digital Transformation in Manufacturing

Machine learning is at the heart of the smart factory revolution. From predictive maintenance to intelligent automation in IT for enterprise, it’s transforming how manufacturers operate, make decisions, and deliver products. Here’s a look at the key ML-based technologies making a big impact in the industry today:

| Technology | What It Is | How It’s Used in Manufacturing |

| Predictive Analytics | Predictive analytics uses ML, statistics, and data mining to forecast outcomes. | It helps manufacturers predict equipment failures, automate quality control, and plan material sourcing. |

| Intelligent Process Automation (IPA) | Combines ML with tools like robotic process automation (RPA) and data analytics services. | Automates repetitive tasks like inventory tracking, vendor communication, and workforce scheduling for greater efficiency. |

| Computer Vision | Form of AI that understands and processes images and videos. | It assists in product inspections, guides assembly robots, and enhances workplace safety by monitoring production zones. |

| Neural Networks | Algorithms that identify patterns and relationships in complex data. | Used for tasks like predictive maintenance, quality control, and optimizing energy usage and product design. |

| Deep Learning | A subset of neural networks that mimics how the human brain learns. | Excels in analyzing massive datasets for detecting defects, forecasting demand, and automating high-precision processes. |

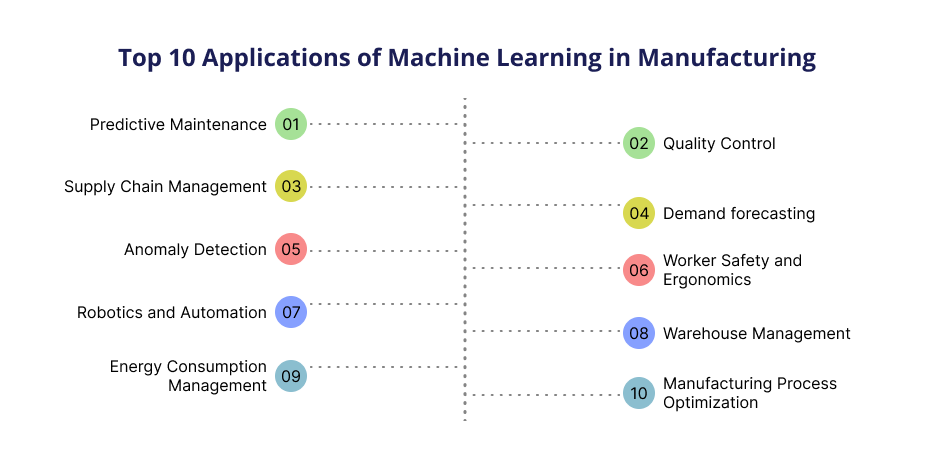

Top 10 Applications of Machine Learning in Manufacturing

Explore impactful applications of machine learning in manufacturing, such as predictive maintenance, quality control, and more. See how these advancements are transforming traditional workflows into highly efficient systems.

1. Predictive Maintenance

Traditional maintenance was prone to errors and often led to unexpected breakdowns and costly downtime. However, by integrating predictive maintenance in machine learning and IoT, companies can:

- Monitor Equipment in real time

- Detect anomalies

- Predict failures

- Enhance operational efficiency

This proactive approach ensures timely repairs, extends machinery life, and increases operational efficiency with data-driven decision-making.

2. Quality Control

ML-powered systems enhance quality control in manufacturing by accurately detecting defects and inconsistencies in products. It also helps reduce manufacturing costs by preventing issues like wasted raw materials.

With ample training data and clear product standards, ML ensures consistent, high-quality output, making it one of the most impactful machine learning use cases and AI-driven industrial automation.

3. Supply Chain Management

Machine learning optimizes supply chain operations by analyzing logistics data, forecasting delays, and identifying cost-effective solutions. Additionally, AI in supply chain management systems also reduces manufacturing costs by lowering scrap levels and rework.

ML solutions assist manufacturers in quickly responding to market fluctuations and strategically aligning their supply chain operations.

4. Demand Forecasting

Demand forecasting in manufacturing is complex, especially with thousands of SKUs. Overstocking and understocking often hurt operations.

However, machine learning models use historical data, customer behavior, seasonality, and market trends to predict inventory needs accurately, helping manufacturers make data-driven inventory decisions with confidence.

5. Anomaly Detection

Machine learning’s strength in pattern recognition and anomaly detection increases manufacturing efficiency. It enables real-time surveillance to spot inefficiencies and prevent costly breakdowns.

When combined with IoT and robotics, industrial machine learning detects issues like abnormal vibrations or warehouse stockouts to improve safety, streamline operations, and enhance overall productivity.

6. Cybersecurity

Machine learning strengthens cybersecurity in manufacturing by detecting anomalies, preventing data breaches, and securing data on-premise, in the cloud, and for connected production environments.

Apart from that, AI in cybersecurity can also protect supply chain networks and digital identities and ensure compliance with industry regulations.

7. Robotics and Automation

Autonomous robots trained on advanced ML algorithms enhance manufacturing by performing complex tasks such as moving materials around a manufacturing facility, installing engines, and mounting doors.

Machine learning in robotics can also help with picking, packing, and palletizing items. An aerial robot or drones can use light object logistics and search for missing tools.

8. Product Development

Forward-thinking manufacturers use neural networks and deep learning for generative design, allowing faster and smarter product development. By inputting resource limits and timelines, machine learning in production generates optimal product designs, cutting production time and improving quality.

This ML-driven approach enhances innovation, minimizes waste, and accelerates time-to-market, making it a game-changer in modern manufacturing.

9. Energy Consumption Management

Machine learning in manufacturing industry identifies energy usage patterns and optimizes consumption, helping manufacturers reduce utility bills and operational expenses.

Moreover, Artificial intelligence in manufacturing uses energy-efficient practices to reduce its carbon footprint and align it with sustainability goals.

10. Worker Safety and Ergonomics

In manufacturing, worker safety remains a top concern, with injuries from overexertion, falls, and harmful exposure still prevalent. AI/ML-powered safety systems now proactively detect risks using sensors and machine vision, triggering alerts before harm occurs.

Wearables with machine learning also monitor posture and motion, offering real-time ergonomic feedback to prevent musculoskeletal disorders and improve workplace safety.

Machine Learning Use Cases Across Manufacturing Sectors

While core machine learning use cases in manufacturing, like predictive maintenance, quality control, and inventory management, are common across manufacturing, certain applications are uniquely tailored to specific sectors. Here’s a breakdown of those industry-specific use cases:

1. Automotive

ML in automotive manufacturing helps with predictive maintenance. Moreover, Generative AI in Automotive Manufacturing boosts quality and precision and helps in generative product design.

- Identify irregularities in a vehicle’s function, like oil levels, tire pressure, engine temperature, etc.

- Quality inspection using computer vision ensures defect-free parts.

- Generate new vehicle designs based on particular parameters.

- Integrating voice assistants to enable hands-free vehicle control and sing emotion recognition to adapt in-vehicle settings based on the driver’s mood.

2. Semiconductors and Computers

Machine learning in electronics manufacturing helps detect defects, optimize assembly processes, and improve productivity.

- Real-time monitoring prevents overheating of circuit boards.

- Examine a video of an assembly line to spot defects.

- Utilizing computer vision to perform automated optical inspection (AOI) on PCBs.

- Streamlining the chip development lifecycle with automated layout verification.

3. Food and Beverage

One of the significant use cases of machine learning is in the food sector. It enables yield prediction, ensures quality control, and streamlines sorting and packaging in food production.

- Analyze historical and environmental data to optimize plant scheduling.

- Automatically notify warehouses to restock shelves.

- Defective products can be rejected by mission-critical programs that scan items.

- Rapidly analyzing ripeness levels in fruits and vegetables using computer vision.

4. Plastic Products

Machine learning is revolutionizing the plastic product manufacturing sector by optimizing production processes and enabling smarter recycling through automation.

- Autonomous sorting of recyclable materials to streamline recycling operations.

- Optimizing injection molding by analyzing mold temperature and pressure for higher-quality outputs.

- Predicting defects in plastic products before they occur using real-time data from sensors.

- Improving material selection by analyzing performance data to choose the right polymers for specific applications.

5. Pharmaceutical Manufacturing

Digital transformation services providers use machine learning in pharmaceuticals to speed up drug development, ensure compliance, and facilitate production processes in pharmaceutical manufacturing.

- Determine possible medications and forecast the new drug’s characteristics.

- Finding the ideal patients for clinical trials can be aided by machine learning.

- Forecast the body’s absorption, metabolism, and excretion of medications.

- Enhancing batch quality by predicting anomalies in pharmaceutical manufacturing.

6. Aerospace

Machine learning in aerospace manufacturing enhances fault detection, streamlines complex assembly tasks, and improves operational safety.

- ML solutions can predict equipment failure, allowing for preventive action.

- To optimize aircraft design, machine learning software development can examine factors like wing loading, airfoil shapes, and engine placement.

- ML for manufacturing can automate QA testing to increase the defect detection rate.

- Improving fuel efficiency through AI-driven flight path and engine performance optimization.

7. Textile

Machine learning in textile industry revolutionizes weaving precision, detects fabric defects, and predicts market trends in the textile industry.

- Automatic fabric quality checks to identify defects and improve production.

- Pattern recognition, color matching, and color recipe creation.

- Demand forecasting helps to align production with fashion trends.

- Recommend optimal dye recipes based on historical colorfastness and material compatibility data.

Global Companies Successfully Using ML in Manufacturing

Leading manufacturers worldwide are embracing machine learning to streamline operations, improve quality, and drive innovation. Let’s look at some successful machine learning in manufacturing examples and see how industry giants are leveraging it to gain a competitive edge.

-

ZF Group

ZF Group uses machine learning in manufacturing to enhance quality control. Their AI-driven systems analyze sensor data in real-time to detect wear, reduce downtime, and ensure product consistency across global plants.

-

Siemens

Siemens integrates ML into its MindSphere platform, helping manufacturers predict machine failures, optimize energy usage, and automate complex production tasks. This ultimately is boosting efficiency and reducing operational costs across industrial settings.

-

General Motors

GM applies to monitor production lines, spot defects, and ensure product quality. Their advanced analytics platforms also support machine learning for manufacturing process optimization and assist engineers in early-stage vehicle design improvements.

-

Veo Robotics

Veo Robotics uses ML-powered computer vision to make industrial robots safer and more collaborative. Their technology enables real-time human-robot interaction, improving worker safety while maintaining productivity on high-speed assembly lines.

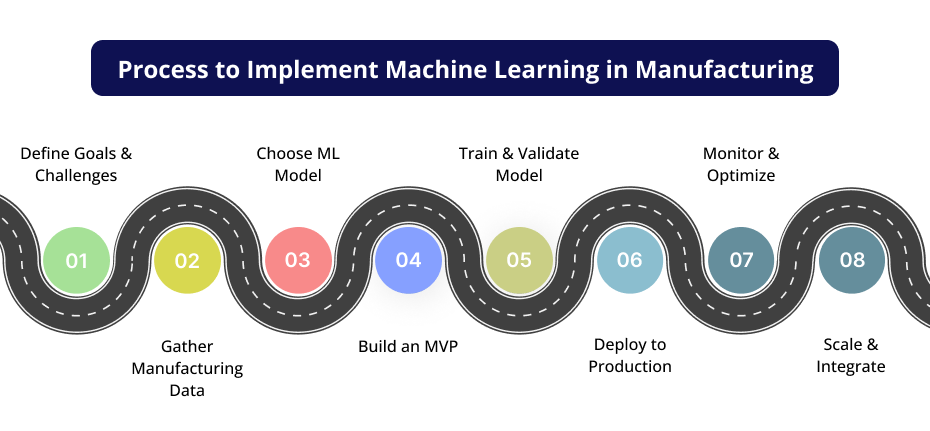

Step-by-Step Process to Implement Machine Learning in Manufacturing

A clear and actionable roadmap is necessary to successfully integrate machine learning into manufacturing operations. Let’s look at the strategic steps to augment ML solutions to drive unprecedented growth and innovation.

1. Identify Business Goals and Challenges

This is the first step to implementing ML in the manufacturing industry. You must clearly outline the manufacturing challenges and business objectives where machine learning can create a measurable impact.

This will ensure that your investment aligns with long-term operational goals. It will help in —

- Develop a detailed implementation roadmap

- Define success metrics and KPIs

- Choose suitable ML application areas

- Allocate technical and financial resources

- Make data-backed strategic decisions

2. Collect Relevant Manufacturing Data

Once your goals are clear, gather high-quality, structured data from manufacturing systems, IoT sensors, and ERP tools. This forms the foundation for building accurate and effective ML models.

Steps to collect proper manufacturing data–

- Collect data from machinery and shop floor systems

- Extract and consolidate data from legacy platforms

- Validate and clean raw datasets

- Ensure consistent formatting and labeling

- Store securely in a centralized database

3. Select an Appropriate ML Model

You can discuss the best-fit ML models with your machine learning development company. Choose algorithms tailored to address specific manufacturing needs.

Businesses must check the compatibility of their data and desired outcomes. The wrong ML model can lead to poor results, wasted resources, and inefficiencies.

Consider these pointers when selecting or developing a large language model—

- Data size, quality, and dimensionality

- Required accuracy, speed, and output formats

- Available computational resources

- Consider training time and scalability

- Align algorithm type with ML objectives (e.g., regression, classification, clustering)

4. Develop an MVP

Before full-scale deployment, build an MVP to test your ML solution’s feasibility and demonstrate business value. It’s a risk-free way to validate assumptions and gather stakeholder support.

This helps identify potential machine learning challenges early in the process.

- Identify scope and key success criteria

- Highlight business use case and ROI

- Gather early feedback from users

- Test performance with real or simulated data

- Eliminate entropy in machine learning

5. Train and Validate Machine Learning Models

With a successful MVP, begin training your ML models using historical and real-time data. Regular functional testing ensures models adapt accurately to real-world manufacturing conditions.

- Split data into training and testing sets

- Apply k-fold cross-validation for reliability

- Preprocess and normalize datasets

- Select and train the optimal algorithm

- Analyze performance using defined metrics

6. Deploy Models into Production Systems

Now, it’s time to integrate the validated ML models into manufacturing workflows. This helps in aligning them seamlessly with existing production systems and processes.

Proper deployment minimizes disruptions and maximizes immediate benefits.

- Build a scalable deployment architecture

- Use CI/CD pipelines for frequent updates

- Monitor accuracy in real-time post-launch

- Containerize models for flexibility (e.g., Docker)

- Consider cloud platforms for enhanced scalability

7. Monitor Performance and Refine Algorithms

You must continuously track model performance, gather feedback to refine algorithms, and adapt to changing manufacturing conditions.

Ongoing monitoring ensures custom ML/AI models remain effective and aligned with goals. To achieve this, you can—

- Monitor KPIs like accuracy, latency, and output consistency

- Detect concept or data drift

- Gather continuous feedback from users

- Update models using retraining techniques

- Test algorithmic updates in sandbox environments

8. Scale and Integrate Solutions

Finally, scale successful ML applications across departments, plants, or regions. Integration with existing technologies ensures your organization benefits from a connected, data-driven manufacturing ecosystem.

Scaling ensures consistent benefits across all production lines and facilities.

- Expand deployment to multiple facilities

- Standardize ML pipelines and workflows

- Integrate with MES, ERP, and IoT platforms

- Leverage cloud infrastructure for scalability

- Automate reporting and cross-departmental actions

Machine Learning Challenges in Manufacturing and How to Solve Them

Explore common hurdles in adopting manufacturing and machine learning solutions and gain practical strategies to overcome data, integration, and scalability challenges for successful implementation.

-

Lack of Clean and Structured Data

One of the biggest challenges in applying machine learning to manufacturing is dealing with messy, unstructured data. Inconsistent inputs make it hard to train reliable ML models, slowing down development and reducing accuracy.

Solution: Implement automated data cleansing and standardization tools to prepare high-quality datasets to ensure more accurate and efficient machine learning model training.

-

Limited Technical Expertise

Many manufacturers struggle to implement ML solutions due to a lack of professional expertise. Without skilled ML developers and data scientists, managing and scaling machine learning becomes a major roadblock.

Solution: Collaborate with a trusted machine learning development services provider that offers access to experienced data scientists and ML engineers who can guide successful implementation.

-

Resistance to Change in Legacy Systems

Legacy systems often resist change, making it difficult to integrate machine learning technology in manufacturing processes. This hesitation can delay innovation and prevent operational improvements.

Solution: Develop proof-of-concept models and involve key stakeholders early on to demonstrate the tangible benefits of machine learning (ML) adoption and build organizational buy-in.

-

Ensuring Data Security and Privacy

Manufacturers handle vast amounts of sensitive operational data, making security and compliance with privacy regulations a top concern when implementing a digital transformation strategy in manufacturing.

Solution: Take the assistance of machine learning consulting companies to conduct regular security audits and vulnerability assessments, and comply with key data privacy regulations like GDPR, HIPAA, or CCPA.

-

Difficulty in Scaling ML Models

As data volumes grow, scaling ML models efficiently becomes increasingly difficult. Many manufacturers face challenges in extending ML capabilities across multiple operations and facilities.

Solution: Leverage cloud-based infrastructure for scalable ML deployment. Regularly monitor performance metrics to fine-tune and expand ML models across broader manufacturing use cases.

The Future of Machine Learning in Manufacturing

Machine learning is set to revolutionize manufacturing by making systems smarter, faster, and more efficient with emerging technologies and innovations. It continues to attract the attention of investors, entrepreneurs, and product developers:

1. TinyML

TinyML brings machine learning capabilities to ultra-low-power devices on the factory floor. By processing data directly at the edge it enables real-time quality control, predictive maintenance, and anomaly detection, without needing constant cloud connectivity or high computing power.

2. AutoML

AutoML is revolutionizing how manufacturers implement AI development services by automating the model development process. It helps teams with limited expertise build, train, and deploy ML models quickly, streamlining production processes and accelerating digital transformation efforts.

3. Generative AI Integration

Generative AI in manufacturing is transforming UI/UX design and prototyping. Manufacturers can now simulate multiple design iterations, optimize supply chains, and personalize products faster, reducing time-to-market and unlocking innovative solutions in previously rigid workflows.

4. Explainable AI

Explainable AI ensures transparency in machine learning decisions, helping manufacturers understand why a model behaves a certain way. This builds trust, aids regulatory compliance, and improves decision-making in safety-critical and quality-sensitive manufacturing environments.

Achieve Operational Excellence with SparxIT’s Machine Learning Development Services

Through SparxIT’s artificial intelligence and machine learning development services, manufacturing companies can optimize operations by uncovering trends, detecting anomalies, and identifying new opportunities across diverse data sources.

Our intelligent manufacturing software enables businesses to develop data-driven production plans utilizing pre-built, high-performance machine learning models. You can hire machine learning developers who offer seamless integration with ERP systems, enhancing efficiency across all business applications.

The predictive power and adaptive learning of AI/ML are already transforming manufacturing. One clear example is predictive maintenance, where ML-driven insights help manufacturers prevent equipment failures and reduce downtime, even at this early stage of adoption.